Bonding in the automotive industry reduces emissions

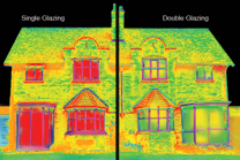

Adhesives and sealants for sustainable development: Material efficiency & Energy savings

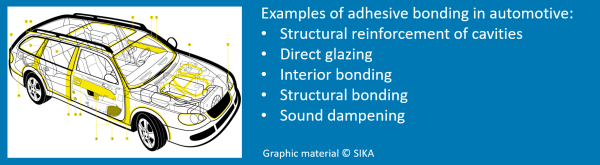

- Adhesive bonding in car production helps to reduce the vehicle’s weight, and thus also the CO2 emission of the finished car.

- Adhesive bonding has also proved to be the most energy efficient joining technique.

- Adhesives and sealants help the car industry to meet its challenges of developing more environmentally-responsible solutions for the future.

Posted 11 Dec 2019

- Emissions from passenger cars account for around half of all CO2 emissions in the transport sector

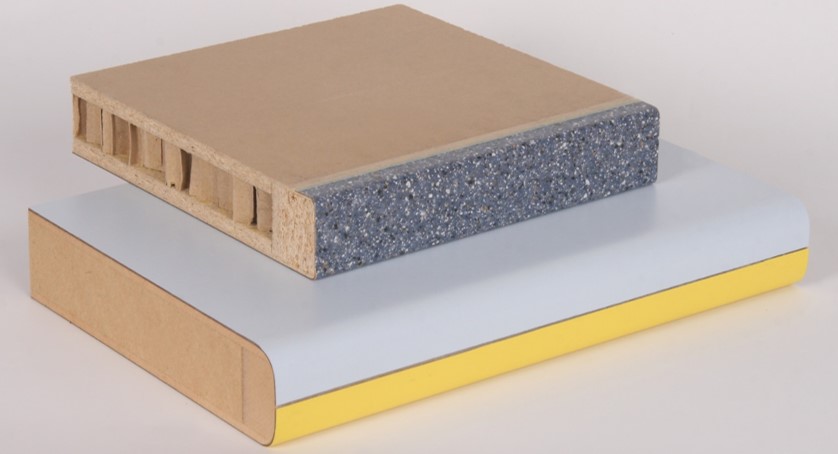

- For steel cars the use of structural adhesives contributes to reduce the weight of a car by at least 15 %. The energy consumption for the production and for the use phase is reduced by more than 15 GJ (equivalent to more than 300 litres of fuel)

- A comparison of joining technologies demonstrates that adhesive bonding has the lowest Global Warming Potential compared to welding and clinching technologies

For more details about this Good Practice, see the Related Document 'Moving more with less CO2 - Bonding in the automotive industry'