Adhesives for bonding floorings to the screed of underfloor heating systems

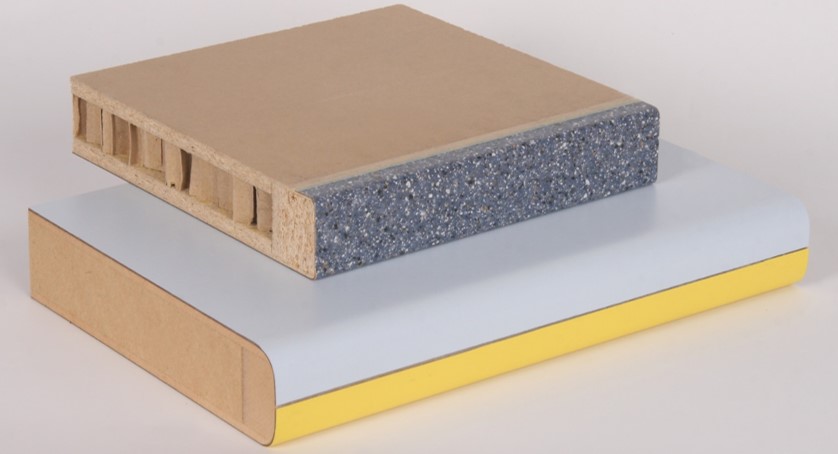

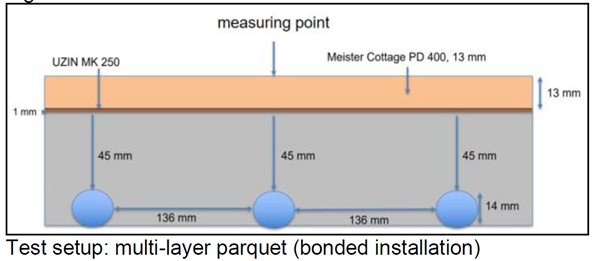

For the parquet flooring, the same material with the same thickness was used for both bonded and floating (loose lay) installation. For the LVT (luxury vinyl tile) flooring the thickness was 2 mm for bonded and 5 mm for floating installation.

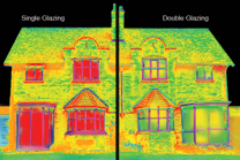

With the same heat flow, bonded installation of the parquet flooring made it possible to reduce the flow temperature of the underfloor heating system by approx. 2 °C; with LVT flooring the flow temperature could be reduced by approx. 3 °C. This leads to an energy saving of 1,64% (parquet) and 2,6% (LVT).

Pictures: TKB

Adhesives/Sealants for Sustainable Development: Energy Savings

Bonding of parquet and LVT (luxury vinyl tile) floorings to the screed of underfloor heating systems with an adhesive instead of a floating installation results in heating energy savings of about 2-3 %.

Parquet is one of the most popular types of flooring. Depending on the type of parquet and the application requirements, a floating or bonding installation is recommended.

The bonding method with modern adhesives is known to have advantages in several aspects of sustainability: durability, renewability by sanding and coating in the case of parquet and heat transfer in the case of underfloor heating.

The heat transfer and energy saving benefits of two types of floor coverings (parquet and LVT) have been investigated in two recent studies.

The flow temperature of the underfloor heating system could be reduced by about 2-3°C with bonded installation depending on the type of floor covering. The lower flow temperature leads to an energy saving of up to 2,6 % compared to the corresponding floating installation.