Biomass balance products to reduce the carbon footprint of adhesives & sealants

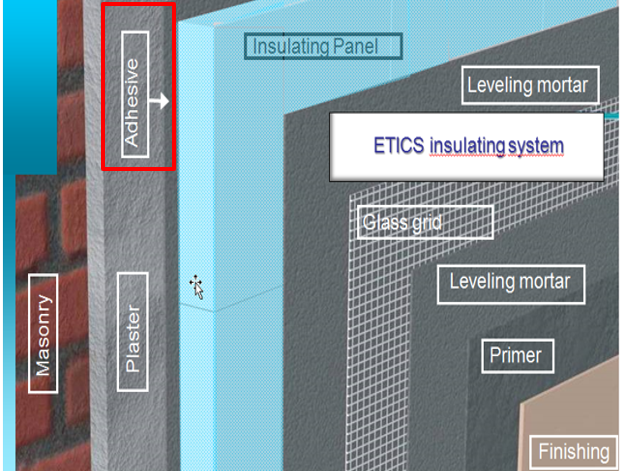

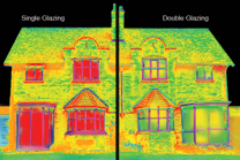

Adhesives/Sealants for Sustainable Development: Energy Savings

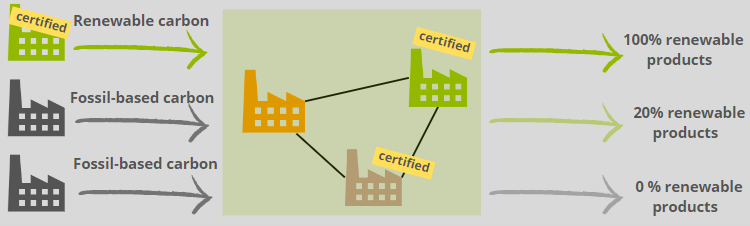

The biomass feedstock is mixed with the fossil feedstock at some stage of the production process and allocated to the end product. The volume of output material is controlled by a certified and audited system. ©Evonik Industries

Examples for A&S:

- MDI (Covestro)

- Poly-α-olefins (Evonik)

Raw material manufacturers offer biomass balance products with the same quality as fossil-based materials. Adhesives & sealants manufacturers can utilise such raw materials as a technical drop-in and benefit from a certified lower carbon footprint.

A&S manufacturers demand a wide range of bio-based raw materials with a lower carbon footprint.

A segregated process to keep the bio-based raw material separated from its fossil equivalent would require a duplication of production equipment or a campaign operation including thorough cleaning, neither reasonable from an economic and ecological perspective. Raw material manufacturers developed the mass balance model which utilises existing infrastructure and yields products with unchanged quality. Thus, the model allows for a gradual transition from a pure fossil-based material, via mixtures, to, finally, a pure raw-material-based alternative.

This model can be certified, for example, by ISCC Plus (International Sustainability & Carbon Certification) to guarantee transparency along the value chain.